Yes, you can weld black steel pipe. Although it is called black iron pipe, this material is actually steel. A black pipe is a mild steel pipe that has been galvanized, as opposed to a regular mild steel pipe that has not been galvanized.

Given the fact that black steel pipe has carbon steel characteristics, it’s obvious that it can be welded. Don’t be misled by the word iron in the name of the pipe; it isn’t a standard iron pipe painted black.

Black Pipe Uses

Black pipe is much stronger than copper, aluminum, and PVC pipes. As well as being long and strong, it has several other benefits, making it a favorite for various uses. Before looking at how it’s welded, we should first examine how it’s used.

The Transport of Gas

Black pipes are commonly used in the gas industry as a form of transportation. There is great sensitivity surrounding gas, and handling it improperly can lead to catastrophic consequences. Black iron has a strong role to play here, particularly when transporting gas and propane.

Here, black pipes are distinguished by their lack of seams, enhancing their strength and safety.

Items for Decorating

The use of black pipes to create interesting decorative pieces has become increasingly popular. In addition to being sturdy, they also look stunning, which is why they are so popular.

The pipes’ black color is unnatural since they are made of regular steel pipe without a substrate coating. Its dark color is attributed to iron oxide.

They have many stylish uses, including cabinets, carts, and bathroom accessories.

Water Transport

Black pipes are used for moving water from water wells and wastewater treatment facilities. Experts say that before using them for transporting gas, black pipes were used to transport water from rivers to farms.

Black Pipe Can Be Welded, But Is It Safe?

Since the black pipes are not galvanized steel pipes, they lack a zinc coating. There is therefore no risk of toxic zinc-oxide fumes being created during welding. There is no need to take any special safeguards or precautions.

Removing the mill scale is a good practice to reduce fumes and ensure a quality weld. The use of a respirator and adequate ventilation is always recommended.

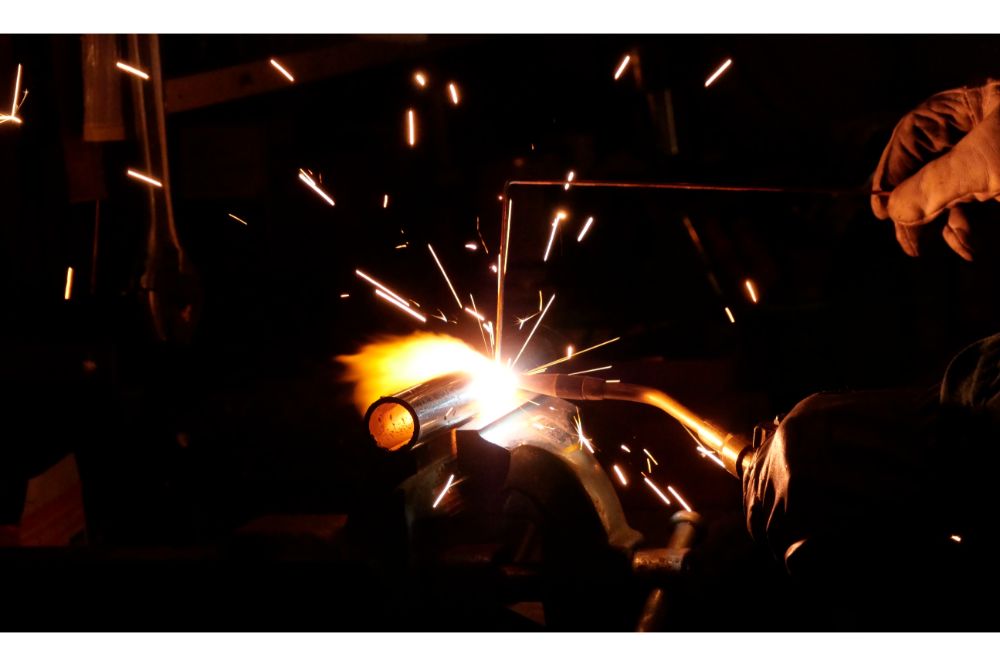

The Welding Process in 6 Steps

To reduce smoke and fumes while at the same time making a better weld, make sure to prepare and clean properly. Surface preparation is important. The metal can also be brightened by brushing or grinding off the dark iron oxide coating.

- If you want to join a black steel pipe with metal, make sure both are clean and tightly clamped together.

- You must decide what welding methodology you will use, set up the equipment, and ensure you wear the appropriate safety equipment.

- It’s advisable to check the welding gun in the area you will be working on, where the two metals meet. Most refer to this as the seam.

- The seams should be melted together to form a bond before you proceed to complete the entire seam.

- Weld the seam between the two metals, turning as needed to form a bead.

- Upon reaching room temperature, brush them to remove any remaining debris.

Are There Any Risks When Welding Black Pipe?

Black iron pipes pose similar welding risks as other welding materials. Because zinc isn’t present in the covering, there are fewer poisonous fumes, but this doesn’t mean it’s safe to weld this material. Poisonous zinc-oxide fumes are fatal, and protecting yourself is important when you are welding.

It’s risky to work with welding guns and materials when welding. To remain protected when dealing with a black iron pipe, you should handle it similarly to other materials.

Shock

When it comes to welding, welders face one of the biggest dangers, and that is electric shock. The hardware used can also be problematic. Messy and wet working environments can cause problems and be dangerous.

Some welding equipment has different voltages, so clients should be prepared before using welding equipment, as well as use protective gear. An experience of this kind is certainly not something anyone wants to have while at work. Always check your gear for worn wires or damage to the cords. Dry gloves must be worn at all times, and you must ensure other protective gear is worn to prevent electric shock.

Breathing in Fumes

Even though black iron pipes do not emit the same harmful fumes as galvanized steel pipes, they still emit gases and vapors that can negatively affect you. Chemicals are still added during the manufacturing process.

Neutral areas should exist where you are working with proper ventilation. Depending on how close you are to another person, fumes may emanate from their work. Always wear a proper gas mask when welding, as you never know what chemicals have been used throughout the manufacturing process that could be harmful.

Various Injuries

Injuries caused by welding are the most obvious danger. There is a strong presence of gas compulsion and extreme heat in the welding process. As a result of poor safety measures, workers may suffer injuries, such as burns and impaired vision. Always ensure protective safety gear is worn at all times, whether dealing with galvanized steel pipes or any other type.

Welding can cause sparks and fires, resulting in metal debris or debris from materials or instruments.

It’s a decent practice to remove mill-scale plant scales and ensure that the weld is high quality. Using a respirator and allowing adequate ventilation are always smart choices.

Precautions Should Be Exercised When Welding Black Pipe Fittings

Additionally, you should remember that black pipe fittings can be difficult to weld. Malleable iron is used to make these fittings. The malleability of iron changes when heated above 1700°F. The iron returns to its original state as cast iron, a brittle material prone to fracture. Make sure malleable iron fittings are brazed or braze welded at low temperatures.

You can also use forged steel socket weld fittings. Welding these will not embrittle the fitting. Steel pipes are welded to steel fittings using your choice of steel-to-steel welding technique. The fittings made of forged steel come in a wide variety of sizes and shapes.

Is Black Pipe Weldable to Steel?

The black pipe is made of low-carbon steel, making it suitable for welding with a wide range of steel grades. It is important to consider several factors before welding it to steel, including metallurgical requirements, thermal treatment, crack zones, and corrosion due to galvanic action.

Methodologies for Welding Black Pipe

Based on what we’ve seen, black pipes can be welded, but what is the best way to do it? Several options are available to you. For example, arc welding, metal inert gas welding, arc welding with flux core, and tungsten inert gas welding.

1. Black Pipes Welded With an Arc

High-pressure welding involves gas or electricity, which creates heat for melting and joining metals. Electric arcs are created between a consumable electrode and a permanently attached electrode with the help of a power supply.

2. Metal Inert Gas Welding

This method uses inert metal gas to perform the same function as arc welding, which uses solid electrodes to fuse metals. The metal is heated using a welding gun.

3. Welding With Flux Cores

A tubular wire filled with flux is used for welding a black pipe. The continuous electrode generates an arc between the workpiece and the continuous electrode. Tubular electrodes contain flux within their cores, which melt while welding, sealing the air around the weld pool.

4. Ignition Control Welding (Tungsten)

The black pipes are welded with tungsten electrodes that cannot be consumed. A pointed tungsten electrode creates an arc between itself and the workpiece in the presence of inert helium.

Pipes Made of Black and Galvanized Steel

Variety of Coatings

Steel is the material that makes up both stirred channels and black pipes. The stirred pipe needs to be zinc-coated, whereas the black tube does not need zinc-coating. Galvanized zinc and black iron differ primarily in that regard.

The Application Is Excellent

Gas lines aren’t run through black pipe since it corrodes quickly. In gas pipelines, zinc can clog up ropes as it crumbles, so galvanized zinc can’t be used. Water lines always need to be installed with electrified pipes.

Corrosion Resistant Design

Black iron pipes provide only the smallest level of security because of their light coating. It will rust outside if left exposed to the elements. The galvanized zinc pipe cannot rust under any circumstances.

Pricing Varies

The cost of black steel is lower than that of galvanized zinc. Galvanized zinc is more expensive due to the additional zinc added to stirred channels.

Conclusion

The black pipe needs to be prepared before welding. The surface of this object is covered with a lot of elements by nature.

Due to its mild low carbon composition, it has many characteristics that make it easy to weld on. In the case of a gas-carrying surface versus a decorative surface, you need to pay close attention to the codes and requirements that must be followed.

Related read: How to Weld Exhaust Pipe